Automated Additive Manufacturing

Manufacturing Futures Institute, Carnegie Mellon University

Role: Industrial Robotics Intern

Mentor: Shobhit Aggarwal

Responsibilities

Creation of a ROS-Industrial Interface for Fanuc and ABB Robot Arms

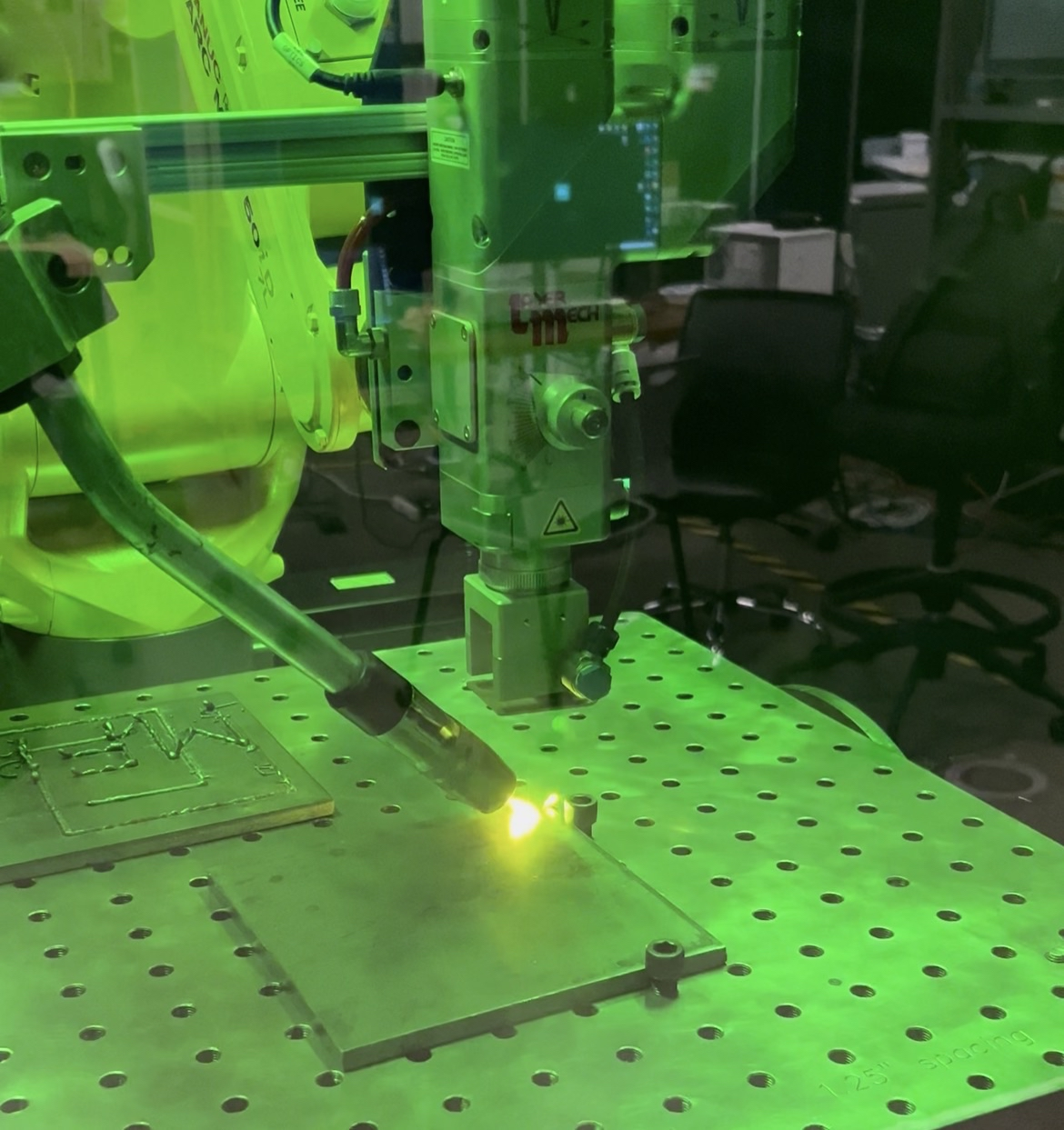

Application: Lincoln Electric Classmate Laser – DXF Pipeline for Additive Manufacturing

DXF Pipeline for Additive Manufacturing

Procedure

- DXF is created and stored

- DXF is called by the working script and parsed into robot poses using

ezdxf - The poses have a fixed z height and end effector orientation as this is a 2D demonstration

- The ROS interface and

Welderclass are launched - The Laser is armed and starts emitting; Welding begins using

comet_rpc -

ExecuteCartesianTrajectoryservice is used to send the rectangle trajectory to the robot and it executes - Laser is disarmed and welding ends

Website: LE Classmate ROS

Additive Manufacturing Process

Custom ROS-Industrial Interface

Features

Interactive Digital Twin - allows moving/observing the robot using a GUI

Broadens scope beyond robot-specific programming - robot can be programmed in both Python and C++

Custom ROS Services allow for trajectory execution with specifications using reliable path planners (Pilz, OMPL, CHOMP)

- Go to a goal point

- Follow a trajectory (multiple goal points)

- Follow a trajectory in a cartesian path

Keyence PLC I/O Control

The ROS interface provides services and topics, interfaced using comet_rpc, to enable I/O control.

All I/O states are polled and published periodically on topics

-

/io_states_AIN- Analog Input Pins -

/io_states_AOUT- Analog Output Pins -

/io_states_DIN- Digital Input Pins -

/io_states_DOUT- Digital Output Pins

ROS Services to access I/Os

-

/set_io_value- allows setting of all types of I/Os (analog/digital) -

/read_io_value- allows reading of all types of I/Os (analog/digital) Hence, all peripheral devices connected to Fanuc I/Os can be controlled using the ROS interface and comet_rpc has been abstracted

Project Impact

| Before | After |

|---|---|

| Only structured text and teach pendant programming | Familiar languages - Python / C++ |

| Trajectories have to be manually taught by jogging the robot | Trajectories can be generated using MoveIt |

| No inputs supported | Complex Inputs Supported |

| No GUI or robot state feedback | Interactive GUI with real-time feedback |

| Robot could only be controlled by teach pendant | Robot can be controlled using GUI, user code and CLI |

Project Links

Website: Fanuc ROS1

GitHub: fanuc_ros1